Site Acceptance Test (SAT) ౼ A Comprehensive Plan

SAT involves verifying system specifications, utilizing checklists, bug reports, and test reports – often documented as a site acceptance test pdf for clarity․

Site Acceptance Testing (SAT) represents a crucial final phase in project delivery, confirming a site’s readiness for operational handover․ Often formalized as a site acceptance test pdf document, SAT ensures installed systems meet predefined specifications and client expectations․ This process isn’t merely a technical verification; it’s a collaborative effort involving stakeholders to validate functionality within the real-world environment․

The SAT process meticulously examines documentation, hardware, and system performance․ Successful completion, documented within the site acceptance test pdf, signifies client approval and initiates the maintenance phase․ Utilizing digital inspection tools and platforms like Google Sites streamlines documentation and reporting, enhancing efficiency and traceability throughout the SAT lifecycle;

Purpose of a Site Acceptance Test (SAT)

The primary purpose of a Site Acceptance Test (SAT), often comprehensively outlined in a site acceptance test pdf, is to validate that the installed system functions correctly within the specific site environment․ This confirms adherence to agreed-upon specifications and ensures the system meets the client’s operational needs․

A detailed site acceptance test pdf serves as evidence of successful implementation and provides a record for future reference․ It minimizes post-implementation issues, reduces risks, and facilitates a smooth handover to maintenance․ Ultimately, SAT, documented thoroughly, guarantees customer satisfaction and a fully functional, reliable system․

SAT vs․ Other Testing Types (UAT, FAT)

While all aim for quality, Site Acceptance Testing (SAT) differs from User Acceptance Testing (UAT) and Factory Acceptance Testing (FAT)․ A site acceptance test pdf details the on-site verification, unlike FAT, which occurs in a manufacturing environment․

SAT confirms functionality within the intended operational location, while UAT focuses on business requirements from the end-user perspective․ Essentially, SAT validates installation and integration, documented in a comprehensive site acceptance test pdf, before UAT confirms usability․ Each phase is crucial for a successful deployment․

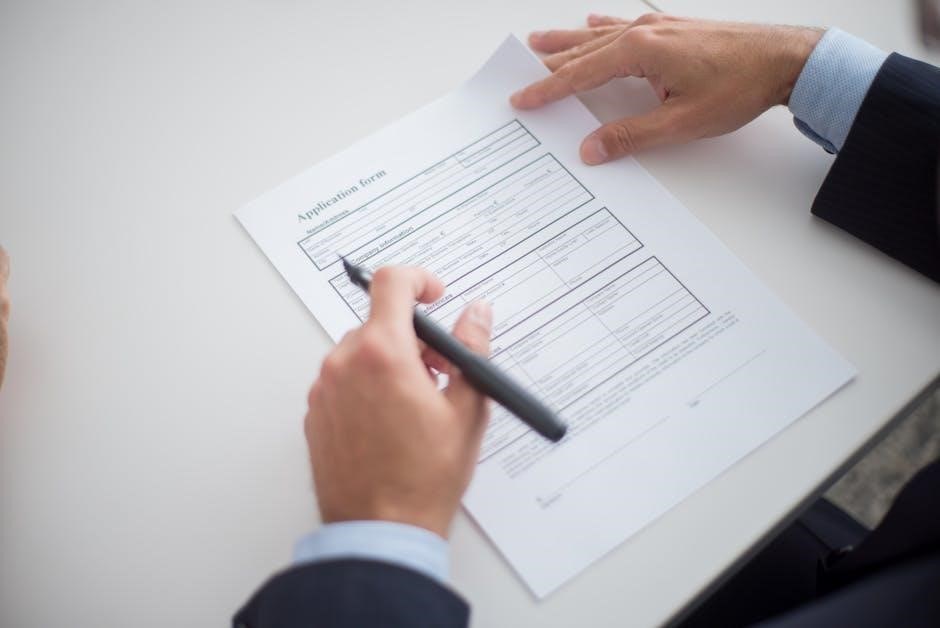

Key Documents for SAT

Successful Site Acceptance Testing (SAT) relies on several key documents, often compiled into a comprehensive site acceptance test pdf․ These include a detailed Test Plan outlining the testing scope and objectives, and Test Case Documentation specifying individual test steps․

Essential are Check-List Templates for efficient verification, Bug Report Forms to track issues, and a final Test Report summarizing results․ A well-structured site acceptance test pdf consolidates these, providing a clear audit trail and ensuring all criteria are met before site handover․

Test Plan Document

The Test Plan Document is foundational to Site Acceptance Testing (SAT), often a core component of a larger site acceptance test pdf․ It defines the testing scope, objectives, resources, and schedule․ Crucially, it details the testing environment, entry/exit criteria, and identifies responsible parties․

A robust plan outlines test strategies, including types of testing and expected outcomes․ It serves as a blueprint, ensuring consistent and thorough evaluation․ Inclusion within the site acceptance test pdf guarantees traceability and provides a reference point throughout the SAT process, aiding in clear communication and issue resolution․

Test Case Documentation

Test Case Documentation meticulously details individual tests within the Site Acceptance Test (SAT) process, frequently included as a vital section within a comprehensive site acceptance test pdf․ Each test case specifies preconditions, input data, expected results, and steps to execute․

Well-defined test cases ensure consistent and repeatable testing, minimizing ambiguity․ They cover specific functionalities and scenarios, verifying adherence to requirements․ Inclusion in the site acceptance test pdf provides a clear audit trail, demonstrating thorough testing and facilitating efficient troubleshooting and re-testing efforts․

Check-List Templates

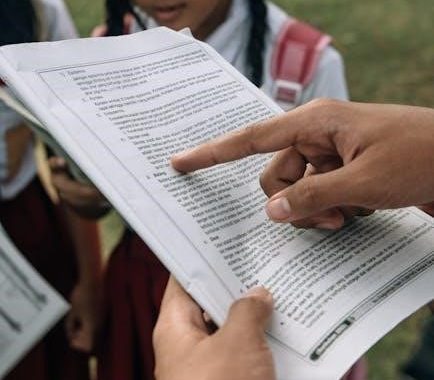

Check-List Templates are crucial components of a successful Site Acceptance Test (SAT), often integrated directly into a detailed site acceptance test pdf document․ These templates provide a structured, itemized list of verification points, ensuring no critical aspect is overlooked during site inspections and system validations․

Utilizing checklists streamlines the testing process, promoting consistency and efficiency․ They facilitate quick identification of pass/fail criteria, simplifying documentation and reporting․ A well-crafted checklist, included in the site acceptance test pdf, serves as a valuable tool for both testers and stakeholders․

Bug Report Forms

Bug Report Forms are essential for documenting any discrepancies discovered during a Site Acceptance Test (SAT), and are frequently included as a section within a comprehensive site acceptance test pdf․ These forms provide a standardized method for detailing issues, including clear descriptions, steps to reproduce, and severity levels․

A well-designed bug report form, part of the site acceptance test pdf, ensures that all relevant information is captured, facilitating efficient communication between testing teams and developers․ This structured approach aids in tracking, prioritizing, and resolving defects, ultimately contributing to a higher-quality deployment․

Test Report Generation

Test Report Generation is the final, crucial step in the Site Acceptance Test (SAT) process, often culminating in a detailed site acceptance test pdf document․ This report summarizes all testing activities, including the scope, methodology, results, and any identified defects․ It provides a clear overview of whether the site meets the defined acceptance criteria․

A comprehensive site acceptance test pdf report should include pass/fail rates, bug report summaries, and a final recommendation regarding site acceptance․ It serves as a formal record for stakeholders and a valuable reference for future maintenance and upgrades, ensuring transparency and accountability․

Preparing for the SAT Process

Preparing for the SAT Process demands meticulous planning and document gathering, often resulting in a consolidated site acceptance test pdf resource․ This includes assembling technical documentation, drawings, and the finalized test plan․ Ensuring all relevant parties – engineers, technicians, and the customer – are aligned on the testing objectives is paramount․

Prior to execution, verify access to the site and necessary tools․ A well-prepared site acceptance test pdf checklist, derived from the test plan, streamlines the process․ Thorough preparation minimizes delays and ensures a focused, efficient, and ultimately successful site acceptance testing phase․

Site Information Verification

Site Information Verification is a crucial initial step, meticulously documented within the comprehensive site acceptance test pdf․ This involves confirming the physical location matches records and assessing environmental conditions impacting installation and operation․ Accurate location confirmation prevents logistical errors and ensures correct equipment deployment․

Environmental assessments, detailed in the site acceptance test pdf, cover factors like temperature, humidity, and potential interference․ These checks guarantee the site meets operational requirements․ Thorough verification minimizes risks and contributes to a successful and reliable system implementation, all clearly outlined in the final report․

Location Confirmation

Location Confirmation, a key component detailed within the site acceptance test pdf, necessitates verifying the physical site precisely matches documented coordinates and addresses․ This prevents deployment to incorrect locations, avoiding costly delays and rework․ Cross-referencing with maps, GPS data, and local records is essential․

The site acceptance test pdf should include photographic evidence confirming the site’s surroundings and accessibility․ Discrepancies must be immediately documented and resolved before proceeding․ Accurate location confirmation ensures proper infrastructure integration and optimal system performance, forming a foundational element of a successful SAT․

Environmental Conditions Assessment

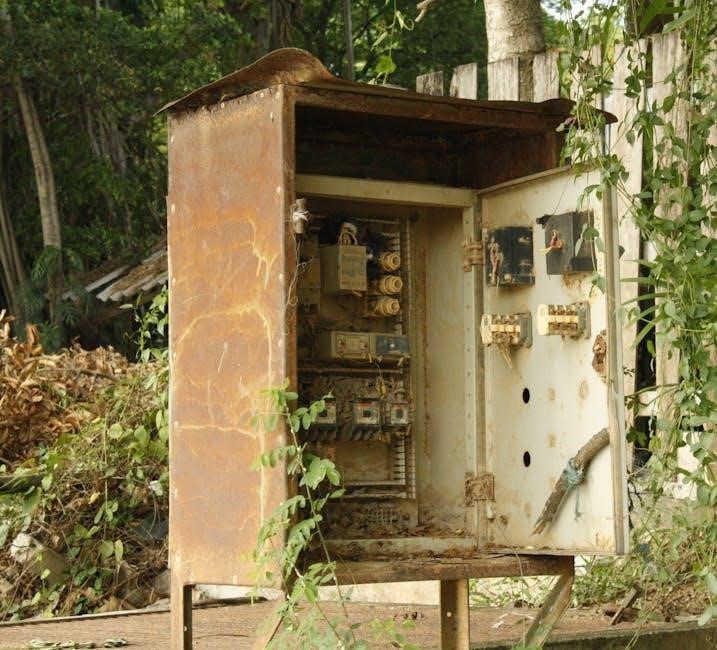

The Environmental Conditions Assessment, thoroughly outlined in a comprehensive site acceptance test pdf, involves evaluating factors impacting equipment functionality․ This includes temperature, humidity, potential for flooding, and seismic activity․ Documenting these conditions ensures the site meets the manufacturer’s specifications and prevents premature failures․

The site acceptance test pdf should detail any necessary mitigation strategies for adverse conditions, such as protective enclosures or grounding requirements․ Proper assessment safeguards equipment longevity and maintains optimal performance․ Ignoring environmental factors can lead to significant operational issues and increased maintenance costs, making this step crucial․

Base Station System Testing

Base Station System Testing, detailed within a complete site acceptance test pdf, focuses on core functionality verification․ This includes rigorous power supply verification, confirming voltage stability and capacity․ A detailed hardware component inspection is also essential, checking for physical damage and correct installation․

The site acceptance test pdf should outline specific tests for each component, documenting pass/fail criteria; Proper testing ensures the base station operates within defined parameters, preventing network disruptions․ Thorough documentation, as found in the site acceptance test pdf, is vital for traceability and future troubleshooting․

Power Supply Verification

Power Supply Verification, a critical section within the site acceptance test pdf, confirms the base station receives stable and adequate power․ This involves measuring voltage and current levels under various load conditions, ensuring they align with manufacturer specifications․ The site acceptance test pdf should detail acceptable ranges and testing procedures․

Testing includes checking grounding, surge protection, and battery backup systems․ Proper power supply function is paramount for reliable operation․ Detailed records, documented in the site acceptance test pdf, are essential for identifying and resolving any power-related issues before site handover, guaranteeing network stability․

Hardware Component Inspection

Hardware Component Inspection, meticulously detailed within the site acceptance test pdf, ensures all physical components are present, undamaged, and correctly installed․ This includes verifying the base station, cabling, connectors, and any associated equipment․ The site acceptance test pdf should list each component and its expected condition․

Visual checks for physical damage, proper seating of cards, and correct labeling are crucial․ Serial numbers are cross-referenced against documentation․ Any discrepancies or defects are documented in the site acceptance test pdf․ Thorough inspection guarantees hardware integrity, preventing future failures and ensuring optimal performance․

Base Station Antenna System Testing

Base Station Antenna System Testing, comprehensively outlined in the site acceptance test pdf, focuses on verifying the antenna’s performance and integrity․ This includes rigorous Antenna Alignment Checks to ensure optimal signal transmission and reception, detailed within the site acceptance test pdf․

Furthermore, the site acceptance test pdf details procedures for Cable and Connector Integrity assessments, checking for damage or loose connections․ VSWR (Voltage Standing Wave Ratio) measurements are critical, documented in the site acceptance test pdf, to confirm efficient power transfer․ Proper antenna grounding and overall system health are also verified․

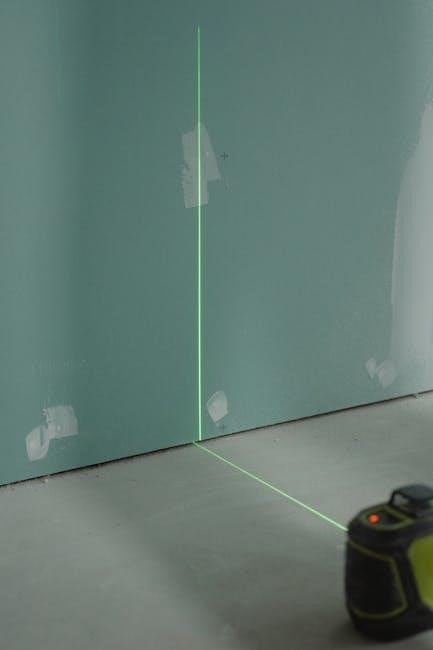

Antenna Alignment Checks

Antenna Alignment Checks, a crucial component detailed within the site acceptance test pdf, ensure optimal radio frequency (RF) signal propagation․ This process, thoroughly documented in the site acceptance test pdf, involves verifying both the azimuth and elevation angles of the antenna, using specialized tools․

The site acceptance test pdf emphasizes the importance of comparing measured angles against the designed specifications․ Any discrepancies identified during these checks, as outlined in the site acceptance test pdf, require immediate adjustment and re-verification․ Proper alignment minimizes interference and maximizes network coverage, as detailed in the site acceptance test pdf․

Cable and Connector Integrity

Cable and Connector Integrity assessments, comprehensively covered in the site acceptance test pdf, are vital for maintaining signal quality․ The site acceptance test pdf details visual inspections for physical damage – kinks, cuts, or crushing – along the entire cable length․

Furthermore, the site acceptance test pdf mandates testing connectors for secure attachment and corrosion․ Utilizing tools like Time Domain Reflectometers (TDRs), as referenced in the site acceptance test pdf, identifies impedance mismatches or cable faults․ Documenting these findings within the site acceptance test pdf ensures a reliable and efficient network connection, preventing signal loss․

Document Review During SAT

Document Review During SAT, as detailed in the comprehensive site acceptance test pdf, is a critical phase․ The site acceptance test pdf emphasizes verifying technical documentation aligns with the installed system․ This includes inspecting drawings for accuracy and completeness, ensuring they reflect the ‘as-built’ configuration․

The site acceptance test pdf outlines a procedure for confirming document schedules are followed, and all necessary paperwork is present․ Discrepancies identified during this review, as noted within the site acceptance test pdf, must be documented and resolved before proceeding․ Proper documentation, guided by the site acceptance test pdf, is essential for future maintenance and troubleshooting․

Technical Documentation Inspection

Technical Documentation Inspection, a core component detailed within the site acceptance test pdf, focuses on verifying the completeness and accuracy of all provided manuals and specifications․ The site acceptance test pdf stresses confirming documentation matches the installed equipment and software versions․ This inspection, guided by the site acceptance test pdf, includes checking for revisions and ensuring all documents are current․

The site acceptance test pdf highlights the importance of verifying that the documentation covers all aspects of the system, from installation to operation and maintenance․ Any missing or incorrect information, as flagged in the site acceptance test pdf, must be addressed before SAT completion, ensuring a smooth handover and future support․

Drawing Verification

Drawing Verification, as outlined in a typical site acceptance test pdf, is crucial for confirming the physical installation aligns with the approved design․ The site acceptance test pdf emphasizes comparing as-built conditions against the original schematics and layouts․ This process, detailed within the site acceptance test pdf, includes verifying cable routes, equipment placement, and antenna configurations․

The site acceptance test pdf stresses identifying any discrepancies between the drawings and the actual site implementation․ Any deviations noted during drawing verification, as documented in the site acceptance test pdf, require immediate investigation and resolution․ Accurate drawings are vital for future maintenance and troubleshooting, as highlighted in the site acceptance test pdf․

VSAT Installation & Commissioning SAT

VSAT Installation & Commissioning SAT, detailed within a comprehensive site acceptance test pdf, focuses on verifying the correct setup and functionality of the Very Small Aperture Terminal․ The site acceptance test pdf outlines tests for signal acquisition, uplink/downlink power levels, and data throughput․ A thorough site acceptance test pdf includes checks on antenna pointing accuracy and polarization․

The site acceptance test pdf emphasizes confirming the VSAT integrates seamlessly with the network infrastructure․ Successful commissioning, as validated by the site acceptance test pdf, ensures reliable communication services; The site acceptance test pdf also details procedures for verifying redundancy and failover mechanisms, crucial for service continuity․

Utilizing Digital Inspection Tools (Mobile Apps)

Leveraging mobile apps streamlines the Site Acceptance Test (SAT) process, often replacing traditional paper-based checklists detailed in a site acceptance test pdf․ These digital tools, referenced within the site acceptance test pdf, enable real-time data capture, reducing errors and improving efficiency․ A well-structured site acceptance test pdf will highlight app features like photo documentation and GPS tagging․

Mobile apps, as outlined in the site acceptance test pdf, facilitate immediate bug reporting and automated test report generation․ Utilizing these tools, as described in the site acceptance test pdf, ensures consistent data collection and faster issue resolution․ The site acceptance test pdf emphasizes the benefits of cloud-based data storage and collaboration․

Google Sites Integration for Documentation

Integrating Google Sites offers a centralized platform for managing Site Acceptance Test (SAT) documentation, including the crucial site acceptance test pdf․ Sites, linked to Google Drive, automatically saves changes, ensuring version control for the site acceptance test pdf and related reports․ Creating dedicated sites simplifies organization and access for all stakeholders involved in the SAT process, as detailed in the site acceptance test pdf․

Saving SAT reports as PDFs within Google Sites facilitates easy sharing and archiving, as highlighted in available guides․ Properly named sites and PDFs, as suggested in the site acceptance test pdf, enhance searchability and maintain a clear audit trail throughout the project lifecycle․

Creating and Naming Sites

When establishing Google Sites for Site Acceptance Test (SAT) documentation, including the essential site acceptance test pdf, the initial creation process adds the site to Google Drive, mirroring other Drive files․ The site name, visible only to the creator, functions as the document name within Drive․ For clarity, name the site descriptively – for example, “SAT – Site IS0010” – to easily locate the associated site acceptance test pdf․

Consistent naming conventions, referencing the specific site and document (like the site acceptance test pdf), are crucial for efficient organization and retrieval of all SAT-related materials․

Saving SAT Reports as PDFs

Maintaining readily accessible records is vital during Site Acceptance Testing (SAT)․ Google Sites facilitates saving completed SAT reports, including the crucial site acceptance test pdf documentation, directly as Portable Document Format (PDF) files․ This ensures document integrity and compatibility across various platforms․

To archive the site acceptance test pdf and other related files, utilize the “Print” function within Google Sites, selecting “Save as PDF” as the destination․ This creates a static, shareable version of the report, ideal for long-term storage and distribution to stakeholders involved in the SAT process․

Huawei 3G Rev1 ATP & SAT Considerations

When conducting Site Acceptance Testing (SAT) for Huawei 3G Rev1 deployments, meticulous attention to detail is paramount․ The ATP (Acceptance Test Procedure) documentation, often available as a site acceptance test pdf, outlines specific verification steps․ These include rigorous hardware inspections, power supply validations, and antenna system performance checks․

Ensure all test results are accurately recorded and compiled into a comprehensive SAT report, ideally saved as a site acceptance test pdf for easy distribution and archiving․ Adherence to Huawei’s guidelines, as detailed in the ATP, is crucial for successful site handover․

Drive Test Report Analysis (Site IS0010 Example)

Analyzing a Drive Test Report, such as the one for Site IS0010, is a critical component of Site Acceptance Testing (SAT)․ These reports validate network performance and coverage, confirming the site meets specified criteria․ Key metrics are compared against pre-defined thresholds, often documented within a comprehensive site acceptance test pdf․

Discrepancies identified during analysis necessitate corrective actions and re-testing․ The final, approved Drive Test Report, alongside the overall SAT documentation – frequently archived as a site acceptance test pdf – serves as proof of successful site validation․

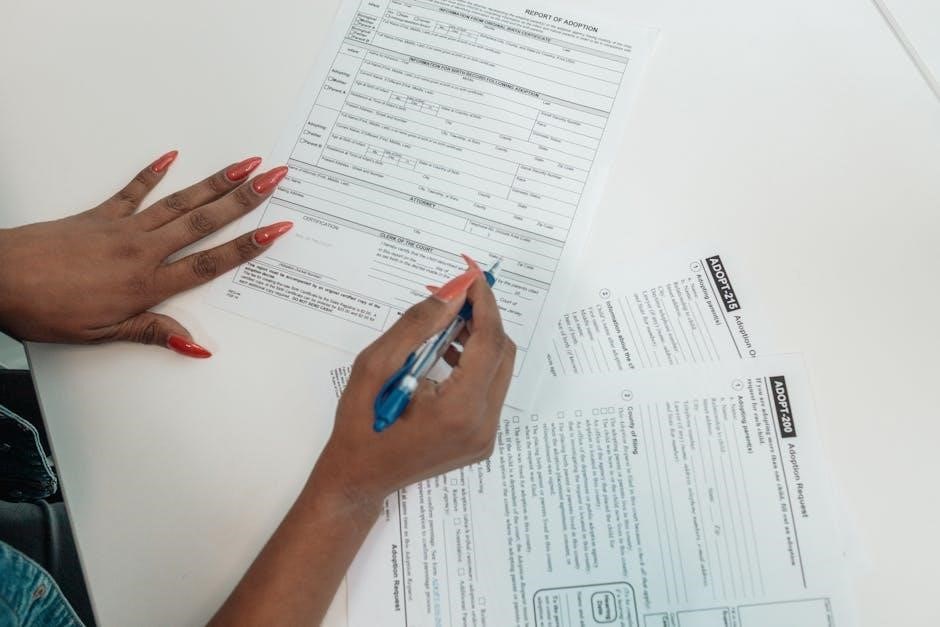

Site Handover Checklist for Maintenance

A detailed Site Handover Checklist ensures a smooth transition from installation to ongoing maintenance․ This checklist confirms all SAT procedures are completed, documentation is in order, and the site is fully operational․ Crucially, it references the finalized site acceptance test pdf, verifying all identified issues have been resolved․

The checklist covers aspects like access permissions, spare parts inventory, and contact information for support․ A signed handover document, including a reference to the approved site acceptance test pdf, formally acknowledges the site’s readiness for long-term maintenance and operational stability․

Acceptance Testing & Customer Insight

Acceptance testing, culminating in the site acceptance test pdf, isn’t merely about technical verification; it’s about providing customers with confidence and insight․ The SAT process allows clients to validate the system meets their specified requirements and operational needs, fostering trust and satisfaction․

Reviewing the detailed findings within the site acceptance test pdf empowers customers to understand the system’s performance and functionality․ This transparency builds a collaborative relationship and ensures the delivered solution aligns perfectly with their expectations, leading to successful long-term adoption․

SAT Checklist Template (Lumiform Example)

Lumiform provides a digital SAT checklist template, streamlining the inspection process and enhancing efficiency․ This template, often compiled into a comprehensive site acceptance test pdf, facilitates meticulous documentation of all testing phases․ Utilizing mobile apps, inspectors can record findings directly on-site, reducing errors and accelerating report generation․

The Lumiform approach ensures consistent and standardized testing, improving the reliability of the SAT results․ The resulting site acceptance test pdf serves as a clear and auditable record, simplifying handover and maintenance procedures, and promoting accountability throughout the project lifecycle․

Common SAT Failure Points

Frequent SAT failures often stem from incomplete documentation, specifically discrepancies between technical drawings and the actual site installation, detailed within the site acceptance test pdf․ Power supply issues and compromised hardware components are also common culprits, requiring thorough verification․ Antenna alignment problems and cable/connector integrity failures frequently necessitate re-testing․

Insufficient environmental condition assessments, or overlooked site information, can lead to failures․ A well-structured site acceptance test pdf should clearly highlight these issues, enabling swift corrective actions and ensuring a successful project handover, minimizing delays and costs․

Corrective Actions & Re-Testing

Upon identifying failures during SAT, documented within the site acceptance test pdf, immediate corrective actions are crucial․ These range from rectifying documentation errors to replacing faulty hardware or re-aligning antennas․ A detailed bug report form is essential for tracking these issues․

Following corrections, rigorous re-testing, mirroring the original test cases, must be performed․ The site acceptance test pdf serves as a record of both initial failures and successful re-tests, ensuring all specifications are met before site handover․ Thorough documentation is key for maintaining quality and accountability․

SAT Completion & Sign-Off

SAT concludes when all test cases, meticulously documented in the comprehensive site acceptance test pdf, are successfully completed and verified․ This signifies the site meets predefined acceptance criteria and is ready for operation․ A final test report, summarizing all findings, is generated․

Formal sign-off requires approval from both the implementing team and the customer, acknowledging acceptance of the delivered system․ This sign-off, appended to the site acceptance test pdf, legally validates the handover and initiates the maintenance phase, ensuring a smooth transition and ongoing support․

Future Trends in SAT – Automation & Remote Testing

The future of SAT, increasingly detailed within evolving site acceptance test pdf documentation, leans towards automation and remote testing methodologies․ Digital inspection tools, like mobile apps (Lumiform), streamline data collection and reporting, reducing manual effort and improving accuracy․

Remote testing, facilitated by advanced monitoring systems, minimizes on-site presence, lowering costs and accelerating the acceptance process․ Expect more sophisticated analytics integrated into the site acceptance test pdf, providing predictive insights and proactive maintenance recommendations, ultimately enhancing network reliability and performance;